| summary: |

The LDC electromagnetic flowmeter is used to detect the flow rate of sewage, pulp, slurry, slurry and other liquids with a conductivity greater than 5 μ S/cm. It is widely used in industries such as petroleum, chemical, steel, food, power, papermaking, water treatment, etc.

| characteristic: |

For harsh working conditions, such as fluids mixed with high concentration mud or bottom conductivity, it can achieve high standard stable measurement;

Measurement is not affected by changes in fluid density, viscosity, temperature, or pressure;

There are no flow blocking components inside the measuring tube, with low pressure loss, maintenance free, and low requirements for straight pipe sections;

The sensor can be equipped with a grounding electrode to achieve good grounding of the instrument;

The sensor adopts advanced processing technology, which enables the instrument to have good pressure resistance;

Full digital processing, strong anti-interference ability, reliable measurement, high accuracy, with bidirectional flow measurement and bidirectional total accumulation function;

◆ HART communication function.

| working principle: |

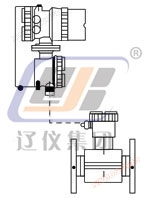

The basic principle of electromagnetic flowmeter is Faraday's law of electromagnetic induction. When a conductor cuts magnetic field lines in a magnetic field, an induced electromotive force will be generated inside the conductor. Apply this principle to measure the flow of conductive liquid inside a tube, with the direction of fluid flow perpendicular to the direction of the magnetic field (see figure). The induced electromotive force generated in the fluid is detected by a pair of electrodes located at the radial ends of the tube. The induced electromotive force (signal voltage) UE is proportional to the magnetic induction intensity B, the distance between the electrodes D, and the average flow velocity V. The magnetic induction intensity B is proportional to the electrode distance D and the average flow velocity V. Due to the constant magnetic induction intensity B and electrode distance D, the induced electromotive force (signal voltage) UE is proportional to the average flow velocity V, and the volumetric flow rate is proportional to the average flow velocity V. Therefore, the volumetric flow rate is proportional to the induced signal voltage. In the signal converter, the induced signal voltage is converted into volumetric flow rate and also into programmable analog and digital signal outputs.

Schematic diagram of electromagnetic flowmeter

| Main technical parameters: |

|

|

|

|

|

Design form |

Integrated type |

Split type |

|

Connection method |

Flange connection |

Flange connection |

|

sensor

|

||||

|

model |

LDC43 |

LDC47 |

LDC41 |

LDC48 |

|

Explosion proof grade |

nothing |

Exd[ia]iamllCT5 |

nothing |

Exd[ia]iamllCT5 |

|

caliber |

DN3-DN2000 |

|||

|

Pressure rating (MPa) |

Standard: 0.6-4.0 (by caliber) Special: According to user requirements |

|||

|

Flange material |

Carbon steel, stainless steel |

|||

|

Lining material |

Rubber, PTFE, PFA, etc |

|||

|

Electrode material |

316, 316L Hb、Hc、 Titanium, tantalum, platinum iridium, etc |

|||

|

Grounding electrode (ring) material |

316, 316L Hb、Hc、 Titanium, tantalum, platinum iridium, etc |

|||

|

conductivity |

≥ 5 μ S/ |

|||

|

Medium temperature |

-40 ℃~180 ℃ (PTFE lining) -25 ℃~65 ℃ (rubber lining) |

|||

|

Protection level |

IP67, IP68 |

|||

|

converter

|

||||

|

Power supply |

24VDC or 220VAC |

|||

|

signal output |

Current 4-20mA, frequency output, pulse output |

|||

|

power waste |

≤ 10W (AC power supply); ≤ 9W (DC power supply) |

|||

|

On site display |

LCD display, instantaneous and cumulative |

|||

|

environment condition |

Environmental temperature: -20 ℃ to 60 ℃; Relative humidity: 5% to 90% |

|||

|

accuracy |

± 0.2%, ± 0.5% (measured values) |

|||

|

Repeatability |

0.2% measurement value |

|||

|

measuring range |

Recommended range of use: 0.3m/s to 10m/s, continuously adjustable |

|||

|

Excitation method |

Excitation frequency 6.25, 12.5, 15, 25, 30Hz |

|||

|

Communication method |

Hart communication (optional), RS485 communication (optional) or fieldbus |

|||

|

Protection level |

IP67 |

IP67 |

||

|

Explosion proof grade |

nothing |

Exd[ia]iamllCT5 |

nothing |

Exd[ia]iamllCT5 |

|

Electrical interface |

M20 × 1.5 or 1/2 "NPT |

|||

|

Shell material |

Cast aluminum |

|||

| External dimensions: |

1. Flange connection: DN3-100

|

caliber |

pressure |

Instrument dimensions (mm) |

Flange connection size (mm) |

Weight (kg) |

|||||||

|

L |

G |

G1 |

C |

D |

K |

n |

d |

Integrated type |

sensor |

||

|

3-8 |

4.0 |

130 |

346 |

234 |

62 |

90 |

60 |

4 |

14 |

5.0 |

4.0 |

|

10 |

4.0 |

200 |

346 |

234 |

62 |

90 |

60 |

4 |

14 |

5.5 |

4.5 |

|

15 |

4.0 |

200 |

346 |

23 |

60 |

95 |

65 |

4 |

14 |

5.5 |

4.5 |

|

20 |

4.0 |

200 |

368 |

256 |

73 |

105 |

75 |

4 |

14 |

6.0 |

5.0 |

|

25 |

4.0 |

200 |

358 |

256 |

73 |

115 |

85 |

4 |

14 |

6.5 |

5.5 |

|

32 |

4.0 |

200 |

378 |

266 |

78 |

140 |

100 |

4 |

18 |

8.0 |

7 |

|

40 |

4.0 |

200 |

386 |

274 |

82 |

150 |

110 |

4 |

18 |

8.5 |

7.5 |

|

50 |

4.0 |

200 |

402 |

290 |

90 |

165 |

125 |

4 |

18 |

10.0 |

9.0 |

|

65 |

4.0 |

250 |

430 |

318 |

104 |

195 |

145 |

8 |

18 |

14.0 |

13.0 |

|

80 |

4.0 |

250 |

442 |

330 |

110 |

200 |

160 |

8 |

18 |

18.0 |

16.0 |

|

100 |

4.0 |

250 |

482 |

370 |

130 |

220 |

180 |

8 |

18 |

19.0 |

17.0 |

1) Other pressure levels can be provided according to user requirements.

2) When the grounding method is the grounding electrode (standard configuration), the DN3-100 caliber and size L remain unchanged.

3) When the grounding method is a grounding ring, install a grounding ring on a single flange with a diameter of DN3-100 and an increase of 3mm in size L.

4) When the grounding method is a grounding ring, install grounding rings on both flanges with a diameter of DN3-100 and an increase of 6mm in size L.

2. Flange connection: DN125-1000

| External dimensions: |

|

caliber |

pressure |

Instrument dimensions (mm) |

Flange connection size (mm) |

Weight (kg) |

|||||||

|

L |

G |

G1 |

C |

D |

K |

n |

D |

Integrated type |

sensor |

||

|

125 |

1.6 |

250 |

466 |

355 |

127 |

250 |

210 |

8 |

18 |

29.0 |

28.0 |

|

150 |

1.6 |

300 |

508 |

397 |

148 |

285 |

240 |

8 |

22 |

31.0 |

30.0 |

|

200 |

1.0 |

350 |

570 |

459 |

179 |

340 |

295 |

8 |

22 |

55.0 |

54.0 |

|

200 |

1.6 |

350 |

570 |

459 |

179 |

340 |

295 |

12 |

22 |

55.0 |

54.0 |

|

250 |

1.0 |

450 |

626 |

515 |

207 |

395 |

350 |

12 |

22 |

80.0 |

79.0 |

|

250 |

1.6 |

450 |

626 |

515 |

207 |

405 |

355 |

12 |

26 |

80.0 |

79.0 |

|

300 |

1.0 |

500 |

712 |

601 |

250 |

445 |

400 |

12 |

22 |

87.0 |

86.0 |

|

300 |

1.6 |

500 |

712 |

601 |

250 |

460 |

410 |

12 |

26 |

87.0 |

86.0 |

|

350 |

1.0 |

550 |

729 |

618 |

250 |

505 |

460 |

16 |

22 |

128.0 |

126.0 |

|

350 |

1.6 |

550 |

729 |

678 |

250 |

520 |

470 |

16 |

26 |

148.0 |

146.0 |

|

400 |

1.0 |

600 |

780 |

669 |

275 |

565 |

515 |

16 |

26 |

153.0 |

151.0 |

|

400 |

1.6 |

600 |

780 |

669 |

275 |

580 |

525 |

16 |

30 |

173.0 |

171.0 |

|

450 |

1.0 |

600 |

829 |

718 |

304 |

615 |

565 |

20 |

26 |

171.0 |

169.0 |

|

450 |

1.6 |

600 |

829 |

718 |

304 |

640 |

585 |

20 |

30 |

193.0 |

191.0 |

|

500 |

1.0 |

600 |

851 |

740 |

310 |

670 |

620 |

20 |

26 |

189.0 |

187.0 |

|

500 |

1.6 |

600 |

851 |

740 |

310 |

715 |

650 |

20 |

33 |

213.0 |

221.0 |

|

600 |

1.0 |

600 |

952 |

841 |

361 |

780 |

725 |

20 |

30 |

245.0 |

243.0 |

|

600 |

1.6 |

600 |

952 |

841 |

361 |

840 |

770 |

20 |

36 |

315.0 |

313.0 |

|

700 |

1.0 |

700 |

1032 |

920 |

405 |

859 |

840 |

24 |

30 |

319.0 |

317.0 |

|

700 |

1.6 |

700 |

1032 |

920 |

405 |

910 |

840 |

24 |

36 |

387.0 |

385.0 |

|

800 |

1.0 |

800 |

1132 |

1020 |

455 |

1015 |

950 |

24 |

33 |

385.0 |

383.0 |

|

800 |

1.6 |

800 |

1132 |

1120 |

455 |

1025 |

950 |

24 |

39 |

450.0 |

448.0 |

|

900 |

1.0 |

900 |

1232 |

1120 |

505 |

1115 |

1050 |

28 |

33 |

487.0 |

485.0 |

|

900 |

1.6 |

900 |

1232 |

1020 |

505 |

1125 |

1050 |

28 |

39 |

589.0 |

587.0 |

|

1000 |

1.0 |

1000 |

1232 |

1120 |

505 |

1230 |

1160 |

28 |

36 |

579.0 |

577.0 |

|

1000 |

1.6 |

1000 |

1232 |

1120 |

505 |

1255 |

1170 |

28 |

42 |

779.0 |

777.0 |

1) Other pressure levels can be provided according to user requirements.

2) When the grounding method is the grounding electrode (standard configuration), the DN125-1000 caliber and size L remain unchanged.

3) LDC41/LDC48 split converter